WELCOME TO CASTMOLD

Aluminum & Zinc Alloy Die Casting — From Prototype to Production

Fast sampling & flexible MOQs, delivered in days.

HPDC + CNC finishing, precision from design to delivery.

ISO 9001:2015 Certified Factory

Our Manufacturing Capabilities

With in-house HPDC machines and a proven Yangtze River Delta supply chain, we achieve ±0.05mm precision in 0.6mm thin-wall casting. Supported by ISO 9001-certified quality control, we deliver rapid prototypes to full production , backed by 2M+ monthly capacity.

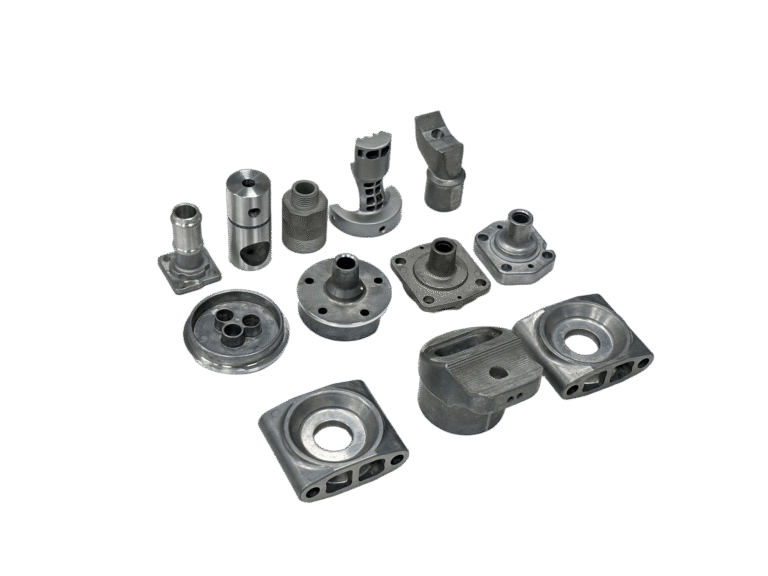

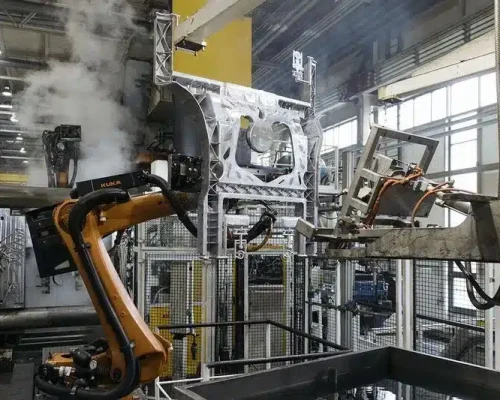

Aluminum Die Casting

High-precision aluminum die cast parts for complex, high-volume applications.

- Minimum batch: 500 pcs

- Minimum wall thickness: 0.5 mm

- Lead times from 15 days

Zinc Die Casting

Choose from Zamak 2/3/5/7 alloys for tight-tolerance, small-part production.

- Minimum batch: 500 pcs

- Minimum wall thickness: 0.5 mm

- Lead times from 15 days

Secondary CNC

3- to 5-axis CNC milling, drilling & turning to refine cast components with ±0.02 mm accuracy.

- Tolerances as tight as ±0.01 mm

- Max workpiece size: 600 × 500 × 400 mm

- Lead times from 7 days

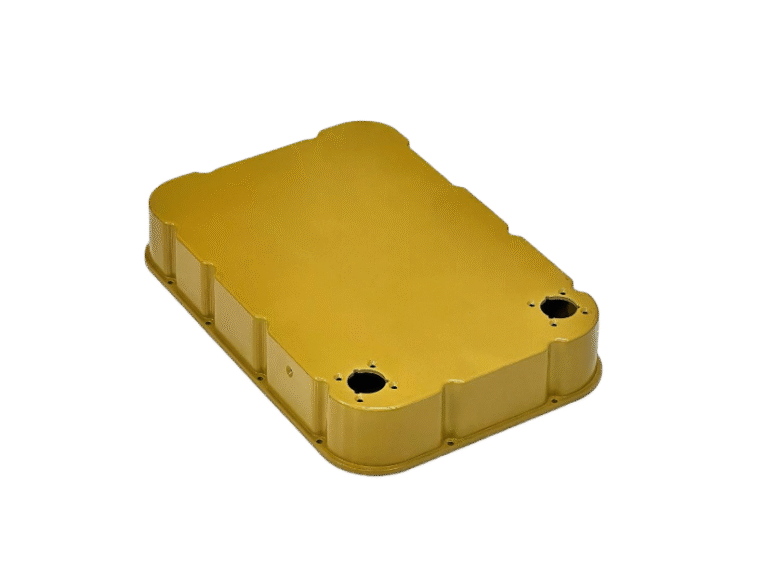

Surface Finishing

Comprehensive finishes—anodizing, powder coat, plating, polishing—to enhance durability and aesthetics.

- Salt spray resistance up to 500 h

- Ra ≤ 0.8 µm achievable

- Custom color & finish options

Rapid Prototyping

Quick-turn prototypes via 3D printing, silicone molding, and soft tooling to validate design fast.

- Sample in as little as 2 days

- Material options: PLA, ABS, urethane, silicone

- Low-volume runs up to 500 pcs

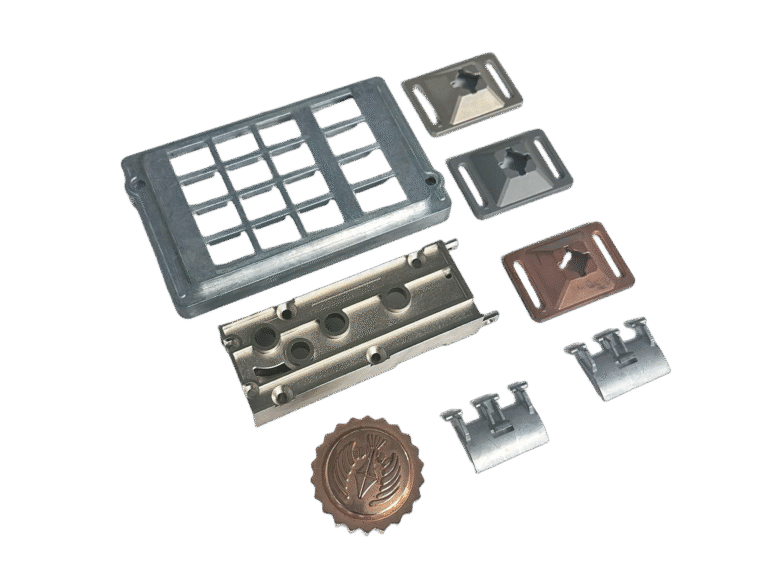

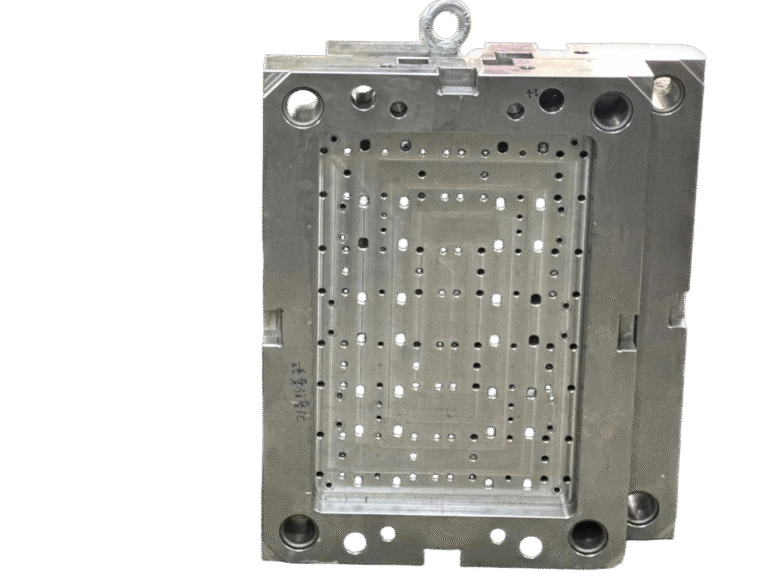

Die Casting Mold Making

Custom mold design and manufacture for aluminum & zinc die casting, ensuring precision and longevity.

- Mold life: up to 50,000 shots

- Cavity options: 1–4 cavities

- Lead times from 4–6 weeks

Total-Solution

Die Casting Services

CastMold owns ISO-certified facilities and partners with vetted workshops across Guangdong. Our integrated network delivers rapid aluminum and zinc die casting, precise CNC machining, and advanced surface finishing at scale—guaranteeing consistent quality and on-time delivery for your custom parts.

Die Casting Factory

- Established: 2010

- Anual Capacity: 10 million pcs

- Number of Machines: 7

- Location: Dongguan

Electroplating Factory

- Established: 2018

- Number of Plating Process Line:10

- Location: Dongguan

3D Printing Factory

- Established: 2018

- Number of Machines: 50

- Location: Dongguan

CNC Workshop

- Established: 2010

- Number of Machines: 10

- Location: Dongguan

Injection Molding Factory

- Established: 2010

- Anual Capacity: 100 million pcs

- Number of Machines:36

- Location: Huizhou

Painting Factory

- Established: 2014

- Number of Powder Coating Line: 5

- Location: Dongguan

Specialist

Industries

Unlock Potential

With the Right Metal

Discover our comprehensive selection of high-quality metals to suit your project needs and ensure optimal performance.

Quality Excellence in Every

Die Casting Component

As a professional metal die casting manufacturer, CastMold embeds precision engineering into every production phase. Our ISO 9001:2015-certified quality system ensures strict compliance with global standards for durable.

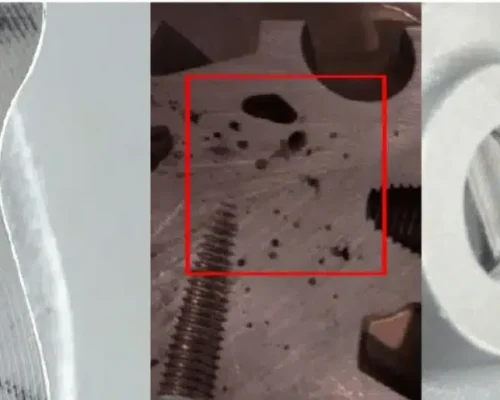

Advanced Measurement, Guaranteed Accuracy

We deploy 10+ precision inspection tools, including CMM for 3D dimensional analysis, two-dimensional measuring instruments for surface flatness, and vernier calipers for micron-level tolerances. This multi-layered verification guarantees your castings meet exact specifications for weight, strength, and dimensional stability.

Rigorous Process Control Across All Stages

Our 10+ skilled quality inspectors implement phased checks:

- Pre-production: Mold integrity validation & material composition testing

- In-process: Real-time monitoring of pressure, temperature, and cycle parameters

- Final inspection: 100% assessment of surface finish, porosity, and mechanical properties

Comprehensive Documentation for Traceability

Clients receive detailed reports including:

- First Article Inspection (FAI) with GD&T analysis

- Material conformity certificates (e.g., ASTM, GB standards)

- Dimensional inspection sheets with CMM point-cloud data

Trusted by Global Partners

Through our ISO 9001:2015 framework, we deliver high-pressure die casting solutions with ≤0.05mm precision for automotive, electronics, and industrial applications.

HOW TO WORK WITH US

Some Number About Us

15 Years Experience

in Die Casting and Prototype Manufacturing.

The Lastest

Blog

Discover our latest insights on die casting innovations, industry trends, and expert tips—straight from the Castmold Blog’s newest post!

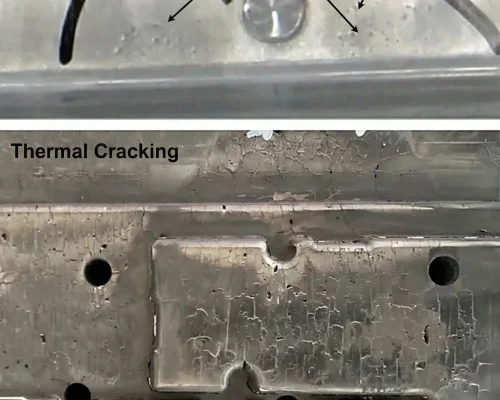

High Pressure Die Casting Mold Steel Selection: How to Balance Life, Cracking and Cost

Die Casting Release Agent Spraying: How to Get Mold Spray Right